Frameless Motor: What it is, How it works, Where to use it ?

Published time:

2025-11-21 18:13

Unleashing Design Freedom: MAINTEX Frameless Torque Motors Redefining New Frontiers in High-Performance Integration

At the forefront of engineering innovation, the shift toward compact, intelligent, and high-performance equipment has become an irreversible trend. Traditional framed motors, constrained by standardized dimensions, mechanical transmission losses, and limited design flexibility, increasingly hinder engineers from overcoming critical bottlenecks. In response to extreme spatial constraints, demands for peak torque response, and the need for seamless integration into overall system architecture, an unconventional solution has emerged — MAINTEX Frameless Torque Motors.

This is more than a motor component; it's a reimagined philosophy of mechanical transmission. By placing the core of the motor—the rotor and stator—directly into your hands, MAINTEX Frameless Motors grant unparalleled design sovereignty. This empowers you to seamlessly integrate the heart of power into every corner of your system.

This article will take you on an in-depth exploration of the core principles and exceptional advantages of MAINTEX frameless motors, while revealing how they play a critical role in top-tier global automation, robotics, and precision systems.

What is a Frameless Motor?

As the name implies, a frameless motor discards the housing, end brackets, and bearing structure of a traditional motor. It retains only the two most essential components for electromagnetic energy conversion: the rotor and the stator.

Rotor: The Source of Rotational Force

MAINTEX rotors utilize high-performance rare-earth permanent magnet materials (such as Neodymium Iron Boron). Through precise magnetization and dynamic balancing processes, they can be accurately mounted inside or outside the stator (forming an outer rotor configuration). As the direct generator of torque, their magnetic field interacts with the stator's magnetic field to achieve highly efficient and exceptionally smooth rotational motion.

Stator: The Precision Commander of the Magnetic Field

As the stationary component of the motor, the stator's core is constructed from low-loss, high-magnetic-permeability laminated silicon steel sheets, paired with high-quality copper windings embedded within. Through advanced winding techniques and insulation treatment, MAINTEX ensures the windings can withstand high-frequency current surges and harsh operating environments, delivering optimal electromagnetic efficiency and reliability.

Beyond the Core: The Complete Ecosystem of MAINTEX Frameless Motor Systems

A comprehensive direct-drive solution extends far beyond just the stator and rotor. MAINTEX is committed to providing a complete ecosystem, ensuring seamless integration for your applications.

Sensing and Feedback Systems:

We offer a range of feedback options, including high-resolution optical encoders, magnetic encoders, resolvers, and Hall effect sensors. These components deliver precise rotor position, speed, and direction information to your controller, forming the foundation for achieving closed-loop precision control.

Advanced Thermal Management Solutions:

The key to sustaining high torque output lies in heat dissipation. MAINTEX motors support multiple cooling methods, including forced air cooling and liquid cooling jacket circulation. Our stator winding design is pre-optimized for efficient heat dissipation and can integrate PT100/1000 temperature sensors to monitor temperature rise in real time. This enables intelligent thermal protection and performance optimization in coordination with your control system.

Customized Mechanical Interfaces:

We provide magnetic sleeves for rotors and aluminum or steel sleeves for stators. Additionally, features such as keyways, threaded holes, and cooling channels can be machined according to your requirements, ensuring perfect rigid integration with your system’s mechanical structure.

How Do MAINTEX Frameless Motors Work?

MAINTEX frameless motors are fundamentally permanent magnet synchronous motors. Their operation is based on the principle of electromagnetic induction: when three-phase alternating current is applied to the multi-pole windings of the stator, it generates a smoothly rotating magnetic field. This rotating magnetic field interacts with the permanent magnet field on the rotor, producing powerful electromagnetic torque that directly drives the load rotation.

As a direct-drive torque motor, it eliminates all intermediate transmission components such as gearboxes, belts, and lead screws. This "zero-backlash" drive method delivers revolutionary advantages:

Extremely High Bandwidth and Response Speed:

the load responds directly to magnetic field variations, eliminating inertial lag and flexible deformation from intermediate components.

Exceptional Precision and Resolution:

Positioning errors resulting from gear meshing backlash, belt elasticity, and slippage are eliminated.

Outstanding Smoothness and Quiet Operation:

With minimal torque ripple, operation is exceptionally smooth, making it particularly suited for applications with stringent requirements for noise and vibration control.

Why Do World-Leading Engineers Choose MAINTEX?

Opting for MAINTEX frameless motors is not merely about selecting a component—it is about embracing a strategic advantage.

Ultimate Space Optimization and Integration Freedom

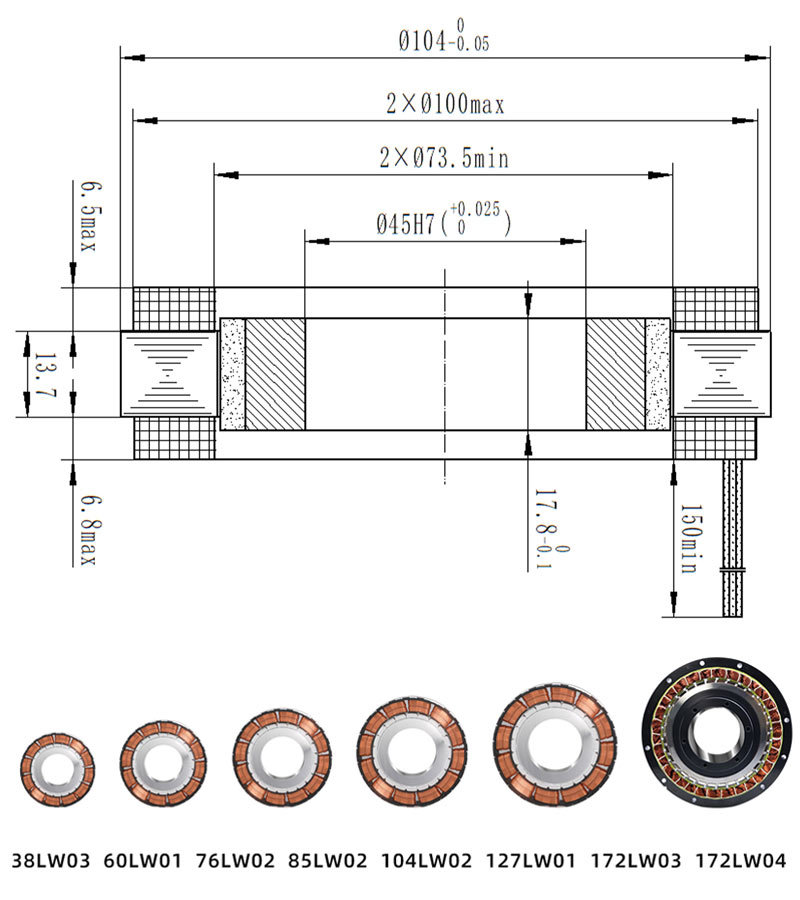

MAINTEX motors offer a broad diameter range from 25mm to 180mm (with customization available for larger dimensions) and flexible thickness options. The hollow shaft design allows wiring harnesses, cooling tubes, vacuum pipelines, or laser paths to pass directly through the center of the motor, significantly simplifying system architecture and enabling a truly "built-in" design.

Peak Torque Density and Performance

Through electromagnetic simulation and optimization, MAINTEX motors achieve globally leading torque output per unit volume and unit weight. Whether your application demands peak torque for instantaneous bursts of power or continuous torque for long-term stable operation, our motors deliver performance that exceeds expectations.

Rock-Solid Reliability and Extended Service Life

By eliminating vulnerable mechanical transmission components (such as gears and belts) and adopting a fully enclosed magnetic circuit design (with no brush wear), MAINTEX motors require minimal maintenance. Their design lifespan far exceeds that of traditional motors, making them particularly suitable for harsh environments where maintenance is challenging or uninterrupted operation is critical.

Comprehensive Customization Services

We understand that standard products cannot meet all innovative demands. MAINTEX offers end-to-end customization, covering electromagnetic solutions, winding parameters, mechanical dimensions, interface design, and sensor selection. Your application requirements are the starting point of our design process.

Exceptional Thermal Performance and Sustained Power

With optimized thermal management and integrable cooling solutions, MAINTEX motors efficiently dissipate internal heat, ensuring consistent high torque output under rated conditions without performance degradation due to overheating (torque derating). This is crucial for applications such as machine tool spindles and high-inertia load drives.

Application Fields of MAINTEX Frameless Motors

MAINTEX frameless motors have become indispensable core power components in numerous high-end applications.

- Humanoid Robots

To meet the joint drive requirements of humanoid robots, MAINTEX has developed a series of direct-drive torque motors with high torque density, low torque ripple, and excellent torque-current linearity. These motors serve as a superior alternative to traditional hydraulic joint mechanisms in humanoid robots. - Collaborative Robots

Used for direct drive in joints, these motors enable high precision, high stiffness, and smooth motion, making them key to enhancing robotic performance. To accommodate the low-voltage characteristics of collaborative robots, we have developed a range of high-torque-density modular torque motors (frameless motors). The integrated hollow-shaft structure of the motor and drive controller effectively meets the requirements for compact and lightweight joint design in collaborative robots. - Quadruped Robots

Optimized for joint drive in quadruped robots, MAINTEX motors provide efficient and reliable motion solutions. Leveraging the advantages of brushless motors—high precision, strong load capacity, and durability—these joint drives ensure low energy consumption and feature compact, lightweight designs. They are widely used in military and security applications, rescue and exploration missions, industrial operations, scientific research and education, as well as various civilian scenarios. - Semiconductor and Electronics Manufacturing

Used in wafer handling robots, wire bonders, and chip mounters, they provide precise, rapid positioning in ultra-clean vacuum environments. - Aerospace and Defense

Driving flight simulators, rudder control mechanisms, radar antennas, and electro-optical pods, they meet extreme demands for high reliability and rapid response. - Medical and Life Sciences

Applied in surgical robots, CT/MRI scanner bed drives, and artificial heart pumps, where silent operation, absence of magnetic interference, and high reliability are critical. - Precision Machine Tools and Machining Centers

Serving as direct-drive rotary tables or motorized spindles, they deliver high-speed, high-precision machining capabilities with zero backlash and high rigidity. - New Energy and Special Vehicles

Utilized in electric vehicle wheel-side drives, air compressors for fuel cells, and steering assist systems for specialized vehicles (e.g., smart agricultural machinery). - High-End Consumer Electronics and VR

Providing instantaneous, realistic haptic feedback for high-end force feedback steering wheels and VR haptic simulation devices.

MAINTEX Product Series: Inrunner Frameless Motor

Compact in size, lightweight, and characterized by high power density and substantial torque output. The product lineup includes both slotted and slotless series, comprising nearly a hundred specifications.

Key Performance Parameters:

- Torque Range: 0.03 N·m to 30 N·m

- Speed Range: 15 RPM to 200,000 RPM

Customization Series

When standard products fall short of your requirements, our engineering team will collaborate with you to develop unique power solutions—from electromagnetic design and material selection to manufacturing processes.

MAINTEX & You: Co-creating Infinite Possibilities

We firmly believe that the best technology seamlessly integrates into your vision and propels it forward. MAINTEX is not just a supplier but a trusted engineering partner. With a dedicated team of over 70 engineers, we are ready to collaborate with you on innovative designs.

Initiate a Custom Consultation

Share your application requirements, performance metrics, and spatial constraints with us. Our senior application engineers will contact you within 24 hours to begin evaluating customized solutions.

Still Struggling to Balance Space and Performance?

Contact the MAINTEX expert team now, and let us demonstrate how exceptional performance and extreme compactness can coexist.

Have Questions About Frameless Drive Technology?

Email us at james.yang@maintexpt.com or call +86-13699794382. Our technical sales engineers are standing by to provide professional, prompt technical support and sample request service

Related news