Why Choose Maintex Brushless Electric Motor?

Save 2,190 kWh Per Motor, Per Year!

At Maintex, we specialize in high-efficiency electronically commutated (EC) motors, designed to deliver superior performance, energy savings, and long-term reliability. Here’s why our EC motors are the ideal choice for your applications:

1.Exceptional Energy Efficiency

- Up to 83% efficiency, significantly reducing power consumption compared to traditional AC motors.

- Lower operational costs—dramatically cuts electricity bills, making them perfect for continuous-use applications like ventilation and cooling systems.

2. Customizable Solutions

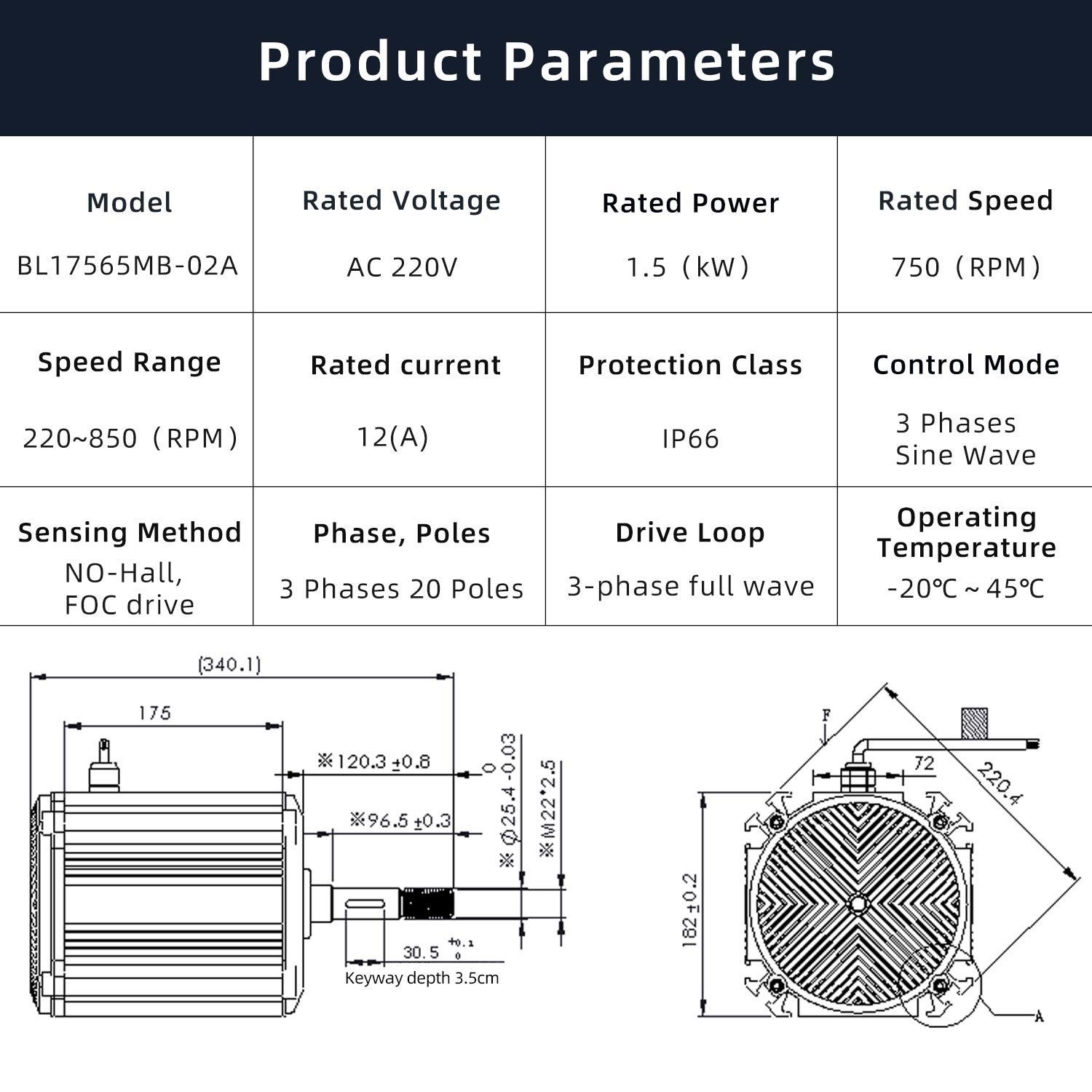

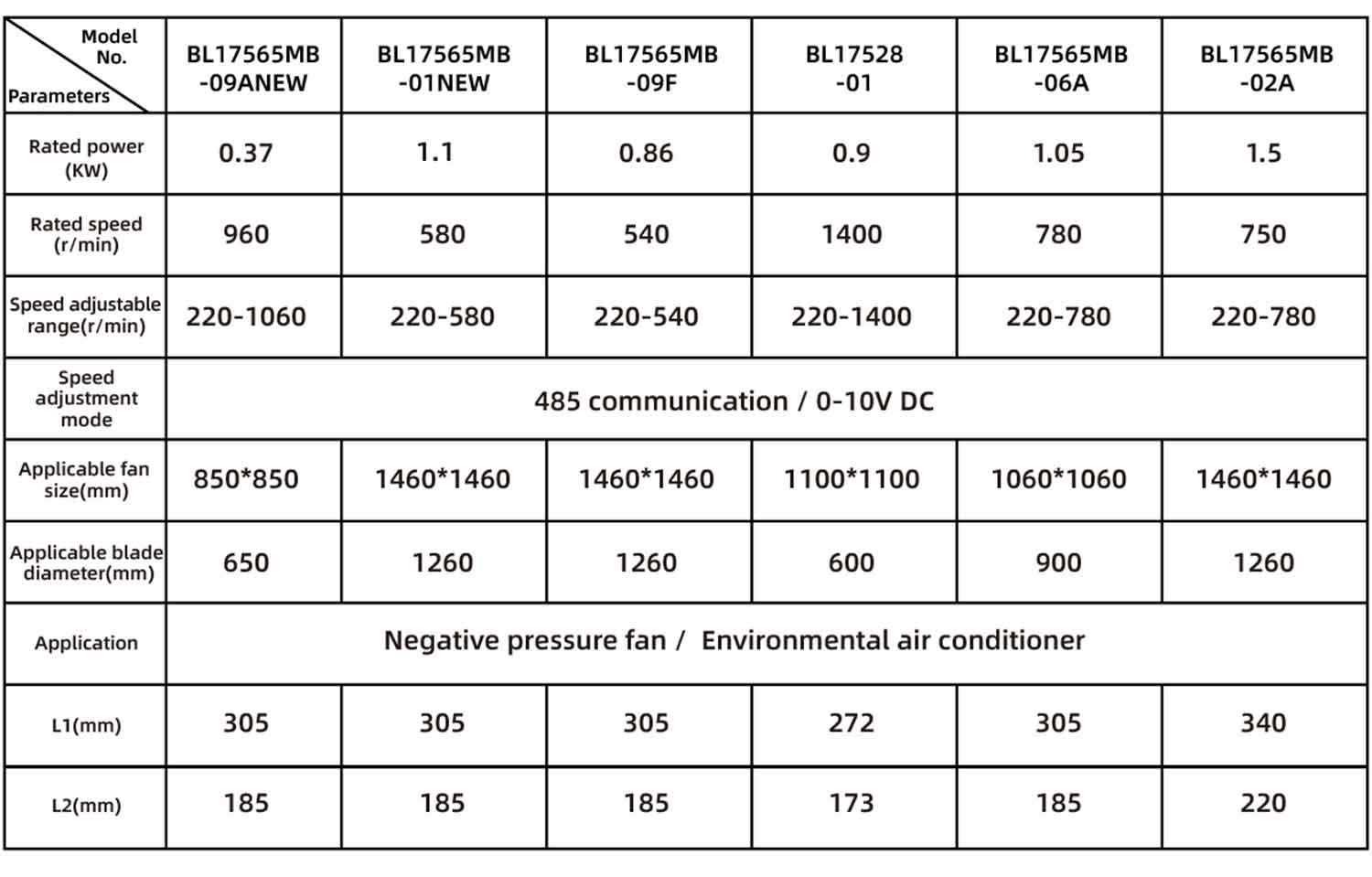

- Wide power range (370W–2200W) to fit diverse needs.

- Adjustable voltage, speed, and power—tailored to your exact requirements.

- Compatible with barn fans, industrial fans, poultry cooling systems, and more.

If the available options do not meet your power requirements, our company also has a strong R&D and design team capable of customizing exclusive motors for you.